- The materials is ready to use, only mix with water and apply.

- This product can be applied by traditional manual application or by modern plastering machines to increase productivity at site.

- It can serve as plaster coat underneath putty for interior use or any other exterior finishes as a subase for application of paints.

- Due to the manufacturing process under controlled conditions, the premix bags gives consistent quality.

- Have good bond strength, crack resistance and water resistance.

- Have good compressive strength.

- Easy to maintain stock as equal size packaging in bag form is provided.

- Cost-effective and user friendly.

- Ready to use & thus saves labour & time.

- The product texture and quality ensures excellent adhesion and makes it slip resistant, giving it an upper edge.

- Crack free and low shrinkage.

- Sufficient flexibility, to accommodate thermal & physical movements. Excellent water proofing characteristics.

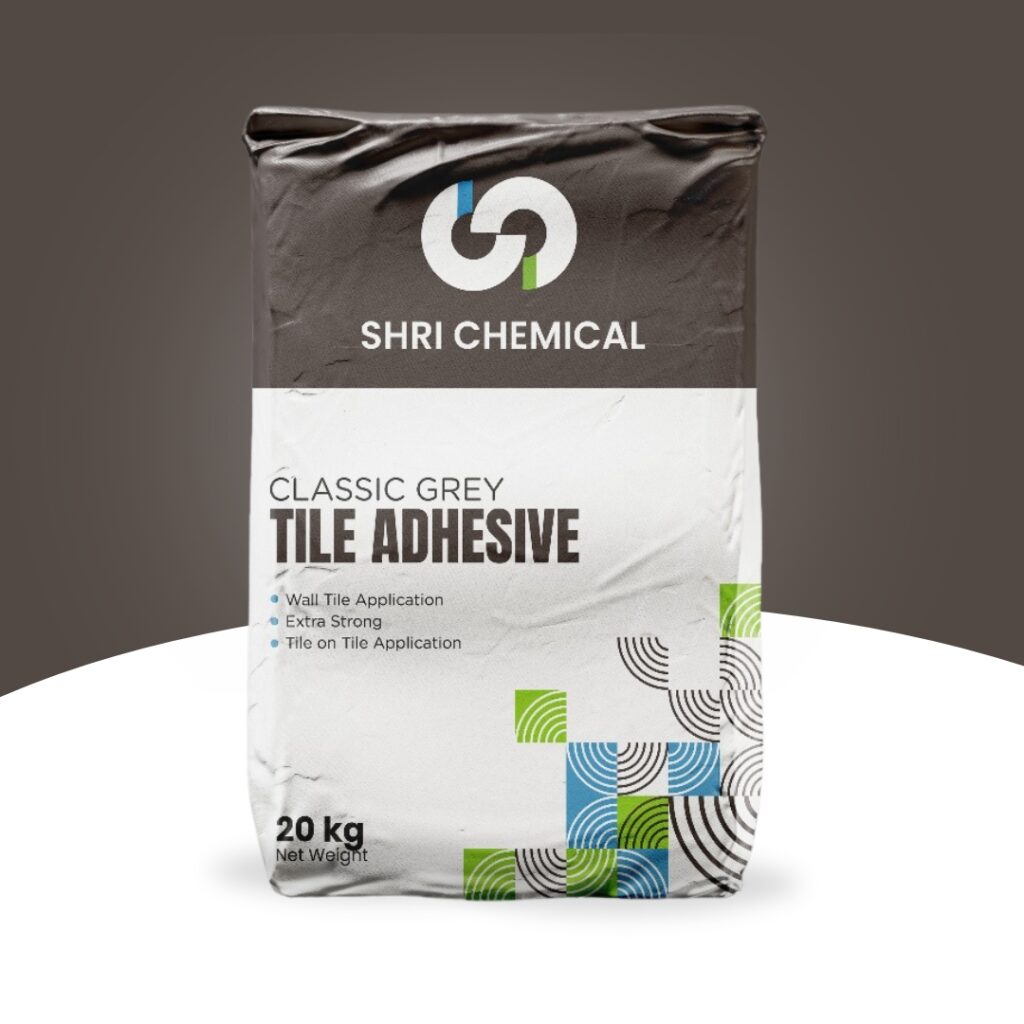

- SHRI CHEMICAL Private Limited offers complete range of Tile Adhesives, a factory made

cementitious dry powder which is mixed with water or special liquid additives to form a

paste, providing problem-free, full bedding tile/stone installation. The thin-set adhesives

have high bonding strength allowing the tiles to directly fixed to the substrate. Manufactured

under stringent quality control procedures, TILOMAX provides long lasting solution for fixing

tiles to any surface, be it ceramic tiles.

- Readymix plaster is a factory premixed sand based cement Plaster.

- Same product can be used for both internal & external application.

- Rmax & Shree chemical readymix plaster can be directly applied in single coat on

brick / block walls, concrete, calcium silicate blocks, AAC blocks etc. - Readymix plaster comprises of high quality ordinary portland cement, graded silica

sand fibers and polymers. - Readymix plaster can be applied to a minimum thickness of 6mm to maximum of 15

mm in single coat. - Where the thickness of application is more than 15 mm, Multiple coats at right

interval is advised. - Superior finish product saves 15-20% putty cost & Paint Cost.

- BJM is ready to use adhesive mortar for fixing AAC blocks, Concrete blocks & fly ash Bricks.

Ready to use, only water to be added. Thinner jointing material with very high tensile

adhesion strength improving the overall masonry strength. Faster to apply due to good

spreadable properties. Excellent high strength & water retention properties. Economical as quantity of mortar is less than conventional mortar with self curing property. Available in 40 kg bag packing.

- Silica sand is one of the most common varieties of sand found in all over the world.

Sand is the general term for broken down granules of minerals or rocks, technically

between about one-sixteenth of a millimeter to two millimeters in diameter. There are

many varieties of sand in the world, each with their own unique composition and

qualities. Silica sand is silicon dioxide containing SiO2.

Our high purity silica sand is widely used as a raw material in industrial processing to

make everyday items such as glass, construction materials, personal care products,

electronics, and even renewable materials.

For industrial and manufacturing applications, deposits of silica-yielding products of at

least 95% SiO2 are preferred. Silica is hard and chemically inert and has a high melting

point, attributable to the strength of the bonds between the atoms. These are prized

qualities in applications like foundries and filtration systems. Industrial sand’s strength,

silicon dioxide (SiO2) contribution, and non-reactive properties make it an indispensable

ingredient in the production of thousands of everyday products.

- Silica sand is one of the most common varieties of sand found in all over the world.

Sand is the general term for broken down granules of minerals or rocks, technically

between about one-sixteenth of a millimeter to two millimeters in diameter. There are

many varieties of sand in the world, each with their own unique composition and

qualities. Silica sand is silicon dioxide containing SiO2.

Our high purity silica sand is widely used as a raw material in industrial processing to

make everyday items such as glass, construction materials, personal care products,

electronics, and even renewable materials.

For industrial and manufacturing applications, deposits of silica-yielding products of at

least 95% SiO2 are preferred. Silica is hard and chemically inert and has a high melting

point, attributable to the strength of the bonds between the atoms. These are prized

qualities in applications like foundries and filtration systems. Industrial sand’s strength,

silicon dioxide (SiO2) contribution, and non-reactive properties make it an indispensable

ingredient in the production of thousands of everyday products.